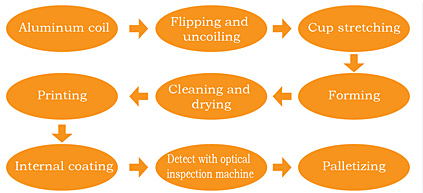

Process

Glossy cans

Ordinary printing is the most widely used in can printing.

Frosted cans

The frosting technology turns the originally smooth can body into a non smooth one, which can make the product more textured and artistic, and enhance the appearance and grade of the product.

Matte cans

The matte technology has a soft and introverted visual effect, and the use of matte oil on a large area makes it more upscale, giving people an elegant and pure, implicit and soft color experience.

White base cans

The white primer technology can achieve beautiful product, full colors without distortion, and good printing result.

Tactile cans

The tactile technology has improved the design of the existing can with a pure smooth surface, improving the appearance of the can body while also improving the tactile feel of the can body, and facilitating stable grip by consumers.

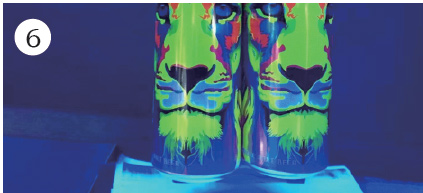

Fluorescent cans

Fluorescence technology is widely used in taverns, KTVs, and other places to enhance product recognition.

FINISHED PRODUCT DISPLAY

From aluminum coils to finished cans, there are 11 major processes and countless small processes. The aluminum coils are flipped and uncoiled, evenly cut, and then enter the cup punching machine for one cup punching and two cup punching