FINISHED PRODUCT DISPLAY

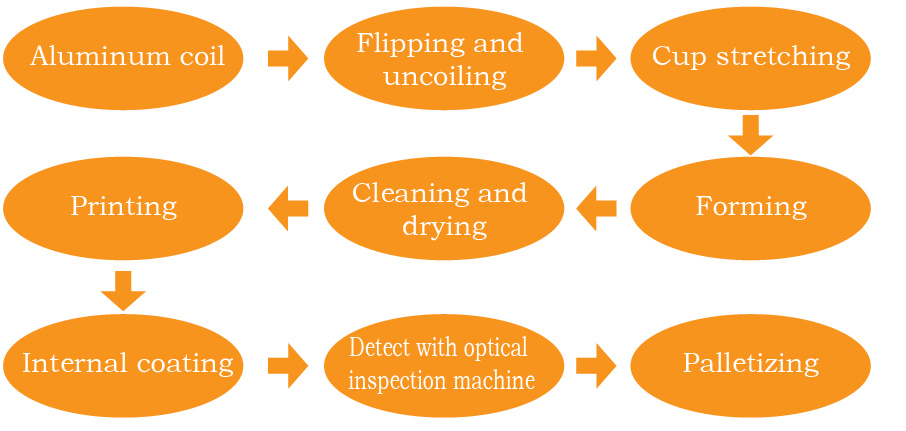

PRODUCTION PROCESS

PRODUCTION / FINISHED PRODUCT DISPLAY

From aluminum coils to finished cans, there are 11 major processes and countless small processes. The aluminum coils are flipped and uncoiled, evenly cut, and then enter the cup punching machine for one cup punching and two cup punching.

After the cup is made, it undergoes edge trimming treatment, followed by rinsing and drying, and then enters the most concerned stage - printing. Unlike paper printing, can printing belongs to letterpress printing, also known as wet to wet printing. Before printing, various color chips suitable for printing are made on aluminum sheet for selection. Printing is the most involved stage, and the colors and patterns of the finished product are completed in this step.